Yes, you absolutely can double up foam board insulation, and doing so is a proven method to significantly boost your building’s thermal resistance (R-value), block more heat transfer, and slash energy costs. For example, research shows that using a double-layer roof structure with foam insulation reduced indoor-outdoor temperature differences by an average of 3.43°C—a 68% improvement in thermal performance. However, success depends on proper installation techniques, material compatibility, and structural considerations.

Why Double-Layer Foam Board Works

Doubling foam board insulation creates a thicker, more continuous thermal barrier. Here’s why it outperforms single layers:

Enhanced R-Value: Each layer adds its own R-value (thermal resistance). For instance, combining two 2-inch XPS boards (R-10 each) can achieve ~R-20, drastically reducing heat flow.

Eliminated Gaps: Staggering seams between layers blocks thermal bridging—where heat escapes through gaps or joints.

Moisture & Condensation Control: A well-sealed double layer acts as a robust vapor barrier, preventing interstitial condensation (moisture trapped between layers), a common failure in single-layer setups.

How to Double Up Foam Board Insulation: 4 Critical Steps

Proper installation ensures maximum efficiency and avoids pitfalls like moisture buildup or structural stress:

Seal All Joints:

Use high-quality foam-compatible tape (e.g., aluminum foil tape) or liquid sealant on every seam in the first layer. This prevents air leaks that undermine insulation.

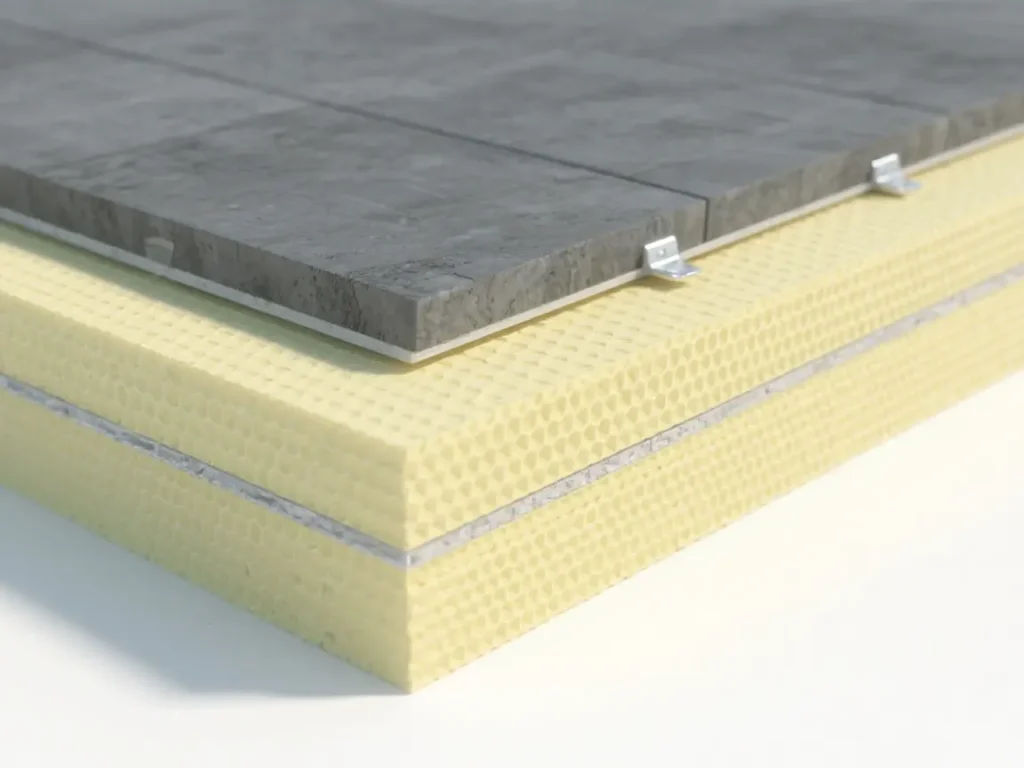

Stagger Seams:

Install the second layer with seams offset by at least 12–24 inches from the first layer’s seams. This eliminates direct pathways for heat escape.

Adhere Securely:

Use mechanical fasteners (washered screws) or construction adhesive rated for foam board. Avoid compressing the foam, which reduces R-value.

Consider Facing:

If using faced boards (foil or plastic coating), place the facing inward (between layers) to prevent vapor trapping.

Unfaced boards are simpler for doubling but require a separate vapor barrier in humid climates.

When Doubling Works Best: Applications & Material Compatibility

Not all foam boards are equally suited for doubling. Key guidelines:

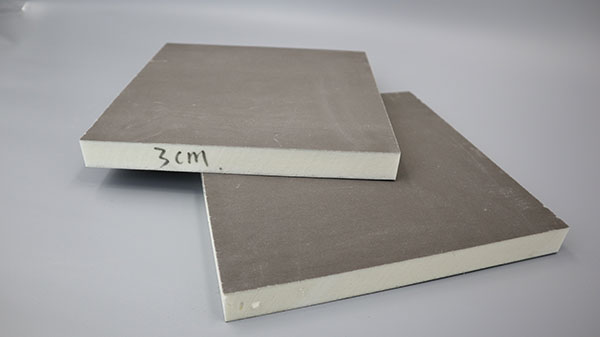

- XPS (Extruded Polystyrene): Ideal for doubling. High compressive strength (up to 500 kPa) handles stacking load, and low water absorption (<1%) prevents degradation.

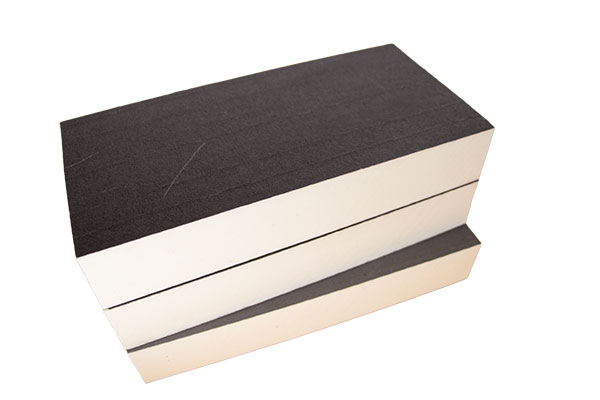

- EPS (Expanded Polystyrene): Use with caution. Lower density EPS (e.g., 1.5–2.5 pcf) may compress under the weight of a second layer. Opt for high-density EPS (>3 pcf) for ceilings or roofs.

- Polyiso: Compatible but avoid stacking near heat sources (>190°F). Its higher R-value per inch (R-6–6.5) makes it efficient for thin double layers.

Avoid doubling: In confined cavities (e.g., wall stud bays), where thickness may impede wiring/venting. Use single thicker boards instead.

Performance Gains: How Much R-Value Improves?

Doubling doesn’t just add R-values—it multiplies effectiveness by reducing thermal bridging:

Theoretical vs. Real Gains: Two R-10 boards theoretically achieve R-20. With proper seam staggering, real-world performance can reach ~R-19 due to minimized gaps.

Reflective Boost: Add an aluminum foil layer between foam boards. Studies show reflective surfaces reduce radiant heat transfer by up to 97%, amplifying overall R-value.

Weight & Space: Practical Considerations

Structural Load: Doubling 1-inch XPS adds ~2.5–4 lbs/sf. Ensure ceilings/roofs can support this (consult an engineer for older buildings).

Space Trade-Off: A double 2-inch layer consumes 4 inches of depth. Alternatives like double-reflective insulation (just 0.2 inches thick) offer similar R-6–8 with minimal space loss—ideal for low-clearance areas.

Alternatives to Doubling Foam Boards

If thickness or weight is prohibitive, consider:

Hybrid Insulation: Combine 1 foam layer with reflective bubble foil (e.g., Foil-Faced Polyiso Foam Board). Achieves R-12–14 at 5/16-inch thickness.

Spray Foam + Board: Seal gaps with spray foam, then add a single foam board. Eliminates thermal bridging better than doubling alone.

The Verdict: When Should You Double Up?

Doubling foam board insulation is highly effective for:

✅ Roofs/floors needing high R-values.

✅ Extreme climates where thermal performance is critical.

✅ New construction or major retrofits with space for thick insulation.

For low-clearance areas (e.g., finished walls), prioritize reflective-vapor barriers or high-R thin foams. Always consult local building codes for fire ratings and vapor requirements.

Pro Tip: In double-layer roof systems (like the Fengman Hydroelectric Plant), pairing foam board with rigid mineral wool boosts fire resistance and thermal efficiency—proven in -42.5°C winters.