If you work in construction or are planning an insulation project, you’ve likely come across a document called a Technical Data Sheet, or TDS. For polyisocyanurate (Polyiso) insulation boards, this sheet is your ultimate guide to the product’s performance and capabilities. However, for many, reading a Polyiso Technical Data Sheets can feel like deciphering a secret code filled with acronyms and numbers.

Don’t worry; you don’t need to be a scientist to understand it. This guide will walk you through a standard Polyiso Technical Data Sheets, explaining every key term in simple, easy-to-understand language. By the end, you’ll be able to confidently compare different products and select the perfect Polyiso board for your specific needs.

What Exactly is a Polyiso Technical Data Sheet (TDS)?

Think of a Polyiso Technical Data Sheets as the insulation board’s resume. Just like a resume tells an employer about a person’s skills and experience, the TDS tells you, the builder, architect, or homeowner, everything you need to know about the insulation’s performance. It contains the results of standardized tests that prove the product’s claims about thermal efficiency, strength, fire safety, and more. Ignoring the TDS is like hiring someone without looking at their resume – it’s a risky move that could lead to problems down the line.

Breaking Down the Key Sections of Your Polyiso TDS

Let’s dive into the most critical parts of the data sheet. We’ll explain what each term means and why it matters to your project.

Understanding Thermal Performance in Polyiso TDS

This is the most important section for most people because it tells you how good the insulation is at saving energy.

- R-Value / Thermal Resistance: This is the star of the show. R-value measures the insulation’s resistance to heat flow. The higher the R-value, the better it insulates. The TDS will list R-values at different temperatures (e.g., at 40°F and 75°F) because Polyiso’s performance is slightly temperature-sensitive. For most comparisons, look at the value at 75°F.

- K-Factor / Thermal Conductivity: This is the raw material property that the R-value is based on. The k-factor measures how easily heat moves through the material. Here, you want a lower number. A lower k-factor means the material is a better insulator, which results in a higher R-value. It’s the “engine” behind the R-value.

- LTTR (Long-Term Thermal Resistance): Because Polyiso uses gas-blowing agents that can slowly diffuse over time, its R-value can stabilize after a few years. The LTTR value is a standardized method that predicts the aged R-value of the insulation after 5 years. It’s the most reliable number to use for long-term energy calculations.

Decoding Physical Properties in the TDS

These properties tell you about the strength and durability of the insulation board.

- Compressive Strength: This measures how much weight or pressure the board can withstand without being crushed. It’s measured in pounds per square inch (psi). If you’re insulating a roof that will have people walking on it or a floor with a heavy load, you need a high compressive strength (often 16-25 psi or higher).

- Dimensional Stability: This test shows how much the board expands or shrinks under extreme heat and humidity. A low percentage change is good. It means the board will stay flat and stable in your walls, preventing gaps and maintaining its performance.

- Water Vapor Permeability: This tells you how resistant the board is to water vapor passing through it. A low “perm” rating means it acts as a vapor retarder, which can be important in certain climates to prevent moisture from getting trapped inside your walls.

Fire Performance and Safety Metrics

Safety is non-negotiable. This section proves the product meets building code requirements.

Flame Spread & Smoke Developed Index: These are determined by a test called the Steiner Tunnel Test (ASTM E84). The flame spread index measures how quickly flames travel across the surface compared to select materials. The smoke developed index measures the amount of smoke generated.

- Red Oak wood has a flame spread index of 100.

- Inorganic reinforced cement board has a flame spread index of 0.

- Most Polyiso boards have a flame spread index of 25 or less and a smoke developed index of 50 or less, which often allows them to achieve a Class A Fire Rating – the best possible rating.

Other Important LSI Keywords in a Polyiso TDS

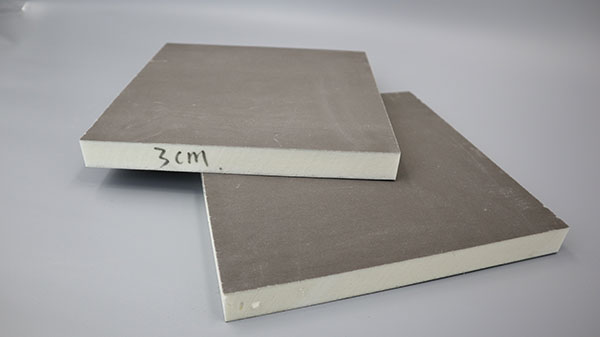

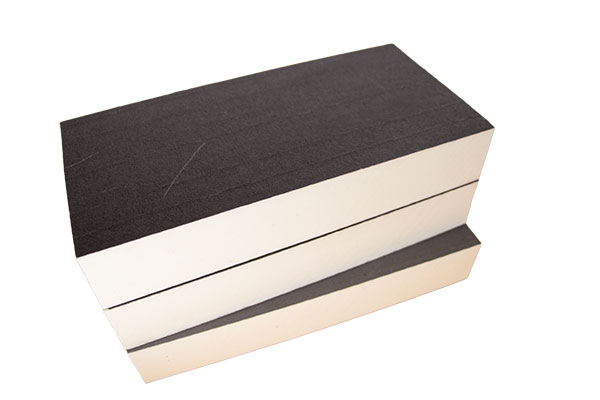

- Facers: The TDS will specify the type of facer on the board (e.g., aluminum foil, glass mat, organic felt). The facer impacts durability, fire performance, and whether the board can also function as a radiant barrier.

- Service Temperature: This is the range of temperatures (high and low) that the board can endure without its performance degrading.

- Environmental Data: You might find information on the Global Warming Potential (GWP) and Ozone Depletion Potential (ODP) of the blowing agents used, which is becoming increasingly important for sustainable building projects.

A Simple Step-by-Step Guide to Reading Any Polyiso TDS

Identify Your Need: What is the primary goal? Is it maximum energy savings (focus on R-value/LTTR), strength for a roof (focus on compressive strength), or fire safety (focus on Flame Spread index)?

Go Straight to the Summary Table: Most TDS have a quick-reference table on the first page. Find your key metrics here.

Compare Apples to Apples: When comparing two brands, ensure you are looking at the same test conditions (e.g., LTTR value vs. initial R-value, compressive strength at the same deformation level).

Check the Fine Print: Look at the facer type, product dimensions, and any special limitations or recommendations.

Conclusion: You Are Now a TDS Expert

Reading a Polyiso Technical Data Sheets doesn’t have to be intimidating. By understanding a few key terms like R-value, LTTR, compressive strength, and flame spread, you can move from confusion to clarity. You now have the power to make an informed, confident decision, ensuring your building project is energy-efficient, strong, and safe for years to come. Always remember to consult the specific TDS for the product you are using and, when in doubt, contact the manufacturer for clarification.