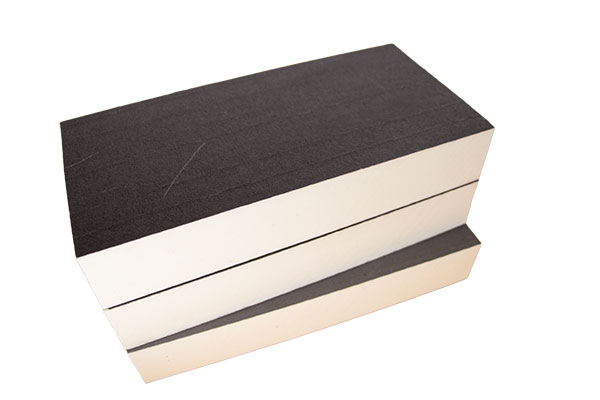

El aislamiento con placas de poliisocianurato (PIR) se ha convertido en una solución de primer nivel para envolventes de edificios energéticamente eficientes, ya que ofrece un rendimiento térmico y una durabilidad excepcionales. Como material aislante de espuma rígida de célula cerrada, se utiliza ampliamente en sistemas de cubiertas comerciales, montajes de paredes y aplicaciones industriales en las que es importante mantener un valor R superior.

¿Por qué elegir paneles aislantes de poliisocianurato?

- Eficiencia térmica líder del sector

Con un valor R de 6,0-6,5 por pulgada (ASTM C518), los paneles PIR ofrecen una resistencia térmica 15-20% superior a la de los aislamientos de espuma de poliuretano o XPS comparables. Su exclusiva estructura de polímero termoestable minimiza la transferencia de calor tanto en climas extremadamente fríos como cálidos. - Mayor seguridad contra incendios

Con una Clase A de resistencia al fuego (ASTM E84), estos paneles aislantes incorporan aditivos ignífugos que resisten la ignición y limitan la formación de humo, una ventaja fundamental frente al aislamiento tradicional de EPS. - Resistencia a la humedad y al vapor

La composición de célula cerrada proporciona una absorción de agua <0,5% (ASTM C272), lo que la hace ideal para el aislamiento de tejados y aplicaciones bajo rasante en las que la resistencia a la condensación es primordial. - Rendimiento respetuoso con el medio ambiente

Contiene 25-30% contenido reciclado y cero agentes agotadores de la capa de ozono, el PIR cumple las normas LEED v4.1 sobre materiales de construcción sostenibles.

Principales aplicaciones de las planchas de espuma rígida PIR

- Sistemas de cubierta plana: 40% más ligero que las cubiertas a base de perlita con prevención de puentes térmicos sin fisuras.

- Sistemas de acabado de aislamiento exterior (EIFS): Obtenga la certificación Passive House con aislamiento continuo

- Almacenes frigoríficos: Mantiene temperaturas constantes con un valor λ de 0,023 W/mK.

- Aislamiento de edificios metálicos: Tableros laminados prefabricados con revestimientos de lámina reforzada

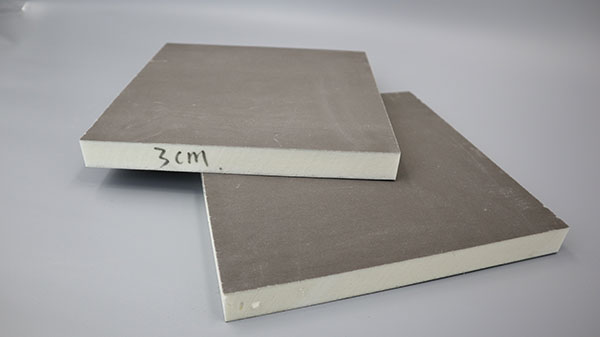

Especificaciones técnicas

| Propiedad | Rango de valores | Norma de ensayo |

|---|---|---|

| Densidad | 30-45 kg/m³ | ASTM D1622 |

| Resistencia a la compresión | 150-250 kPa | ASTM D1621 |

| Temperatura de servicio | -50°C a +110°C | ES 1604 |

| Envejecimiento térmico | <2% cambio de espesor | EN 1604 (70°C/90d) |

Ventajas competitivas frente a otros aislamientos

- 28% Mayor valor R que el poliestireno extruido (XPS) del mismo grosor

- 50% Peso más ligero frente a los tableros de espuma fenólica

- Instalación 3 veces más rápida en comparación con el aislamiento de fibra de vidrio

- Cero emisiones de COV a diferencia de algunas espumas de poliuretano en spray

Buenas prácticas de instalación

- Utilice adhesivos de poliuretano con certificación ISO 9001 para pegar la placa al sustrato.

- Juntas escalonadas en varias capas para eliminar los espacios de aire

- Aplicar revestimientos protectores (lámina/fibra de vidrio) en entornos de alta humedad

- Mantener juntas de dilatación de 6 mm a temperaturas inferiores a 5°C