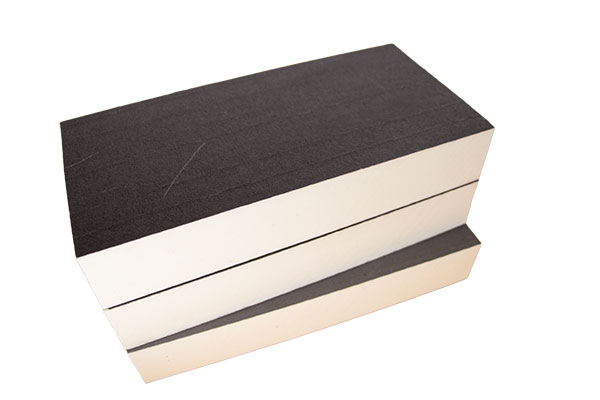

Polyisocyanurat (PIR)-Dämmplatten haben sich zu einer erstklassigen Lösung für energieeffiziente Gebäudehüllen entwickelt und bieten eine außergewöhnliche Wärmeleistung und Haltbarkeit. Als geschlossenzelliger Hartschaumdämmstoff wird er häufig in kommerziellen Dachsystemen, Wandkonstruktionen und industriellen Anwendungen eingesetzt, bei denen es auf eine hohe R-Wert-Beständigkeit ankommt.

Warum sollten Sie sich für Polyisocyanurat-Dämmplatten entscheiden?

- Branchenführender thermischer Wirkungsgrad

Mit einem R-Wert von 6,0-6,5 pro Zoll (ASTM C518) bieten PIR-Platten einen um 15-20% besseren Wärmewiderstand als vergleichbare Polyurethan- oder XPS-Schaumisolierungen. Ihre einzigartige duroplastische Polymerstruktur minimiert die Wärmeübertragung sowohl in extrem kalten als auch in heißen Klimazonen. - Erhöhte Brandsicherheit

Ausgestattet mit einem Feuerwiderstandsklasse A (ASTM E84) enthalten diese Dämmplatten flammhemmende Zusätze, die einer Entzündung widerstehen und die Rauchentwicklung begrenzen - ein entscheidender Vorteil gegenüber herkömmlichen EPS-Dämmstoffen. - Beständigkeit gegen Feuchtigkeit und Wasserdampf

Die geschlossenzellige Zusammensetzung bietet eine Wasserabsorption von <0,5% (ASTM C272) und ist damit ideal für die Dachisolierung und für Anwendungen unter dem Boden, bei denen Kondensationsbeständigkeit von größter Bedeutung ist. - Umweltverträgliche Leistung

Enthält 25-30% recycelter Inhalt und ohne ozonabbauende Stoffe entspricht PIR den LEED v4.1-Standards für nachhaltige Baumaterialien.

Hauptanwendungen von PIR-Hartschaumplatten

- Flachdach-Systeme: 40% leichter als Dächer auf Perlitbasis mit nahtlosem Wärmebrückenschutz

- Systeme zur Außenisolierung (EIFS): Passivhaus-Zertifizierung mit durchgehender Dämmung erreichen

- Gekühlte Lagerhäuser: Konstante Temperaturen mit einem λ-Wert von 0,023 W/mK aufrechterhalten

- Isolierung von Metallgebäuden: Vorgefertigte laminierte Platten mit verstärkten Folienoberflächen

Technische Daten

| Eigentum | Wertebereich | Test Standard |

|---|---|---|

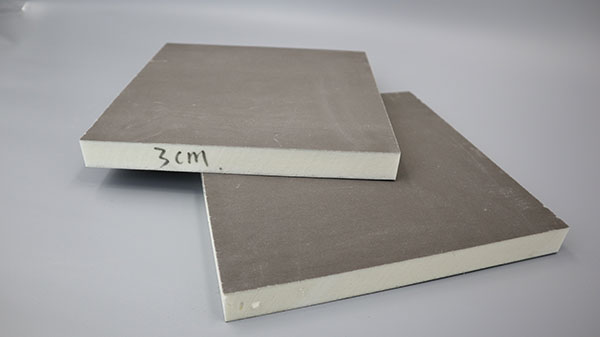

| Dichte | 30-45 kg/m³ | ASTM D1622 |

| Druckfestigkeit | 150-250 kPa | ASTM D1621 |

| Betriebstemperatur | -50°C bis +110°C | EN 1604 |

| Thermische Alterung | <2% Dickenänderung | EN 1604 (70°C/90d) |

Wettbewerbsvorteile gegenüber alternativen Dämmstoffen

- 28% Höherer R-Wert als extrudiertes Polystyrol (XPS) mit gleicher Dicke

- 50% Leichteres Gewicht gegenüber Phenolharzschaumplatten

- 3x schnellere Installation im Vergleich zu Glasfaserdämmplatten

- Null VOC-Emissionen im Gegensatz zu einigen Polyurethan-Sprühschäumen

Bewährte Praktiken bei der Installation

- Verwenden Sie ISO 9001-zertifizierte Polyurethan-Klebstoffe für die Verklebung von Platten mit Untergründen.

- Versetzte Fugen in mehreren Schichten zur Vermeidung von Luftspalten

- Aufbringen von Schutzschichten (Folie/Glasfaser) in Umgebungen mit hoher Feuchtigkeit

- 6mm Dehnungsfugen bei Temperaturen unter 5°C einhalten