Строительная отрасль сталкивается с постоянной дефицит полиизоляцииВ результате срываются сроки реализации проектов и увеличиваются расходы. Этот кризис вызван сложным взаимодействием сбоев в цепочке поставок, растущего спроса и производственных ограничений. Вот анализ основных причин и их последствий, основанный на данных.

1. Узкие места в цепочке поставок и нехватка сырья

Нарушение цепочки поставок полиизола начался во время пандемии, но усугубился из-за геополитической напряженности и логистических препятствий. Ключевые вопросы включают:

Нефтехимическая зависимость: В основе полиизола лежат изоцианаты (MDI/TDI), получаемые из нефти. Волатильность цен на сырую нефть (усугубленная российско-украинским конфликтом) привела к росту стоимости сырья на 30-50% в 2024 году.

Влияние тарифов: Тарифы США на китайский импорт (включая изоляционные химикаты) увеличили затраты на 25%, что создало нагрузку для производителей, зависящих от азиатских поставщиков.

Логистический тупик: Перегруженность портов и задержки в перевозках снизили доступность материалов, а сроки выполнения заказов увеличились с 2 недель до 3 с лишним месяцев.

2. Растущий спрос опережает производственные мощности

Рост спроса на полиизол резко возросла под влиянием нормативных и рыночных факторов:

Строительный бум: Мировая строительная активность, особенно в Северной Америке и Азиатско-Тихоокеанском регионе, выросла на 7% по сравнению с прошлым годом. Только на жилые объекты приходится 40% поставок полиизола.

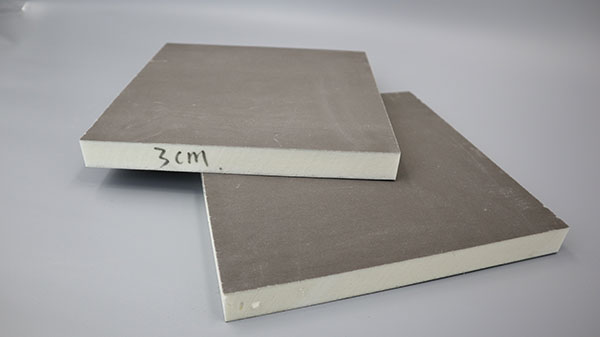

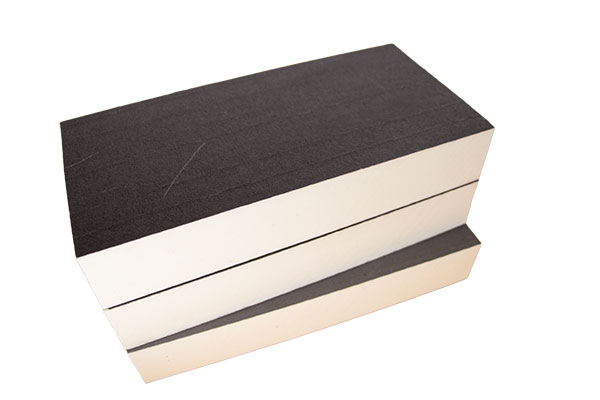

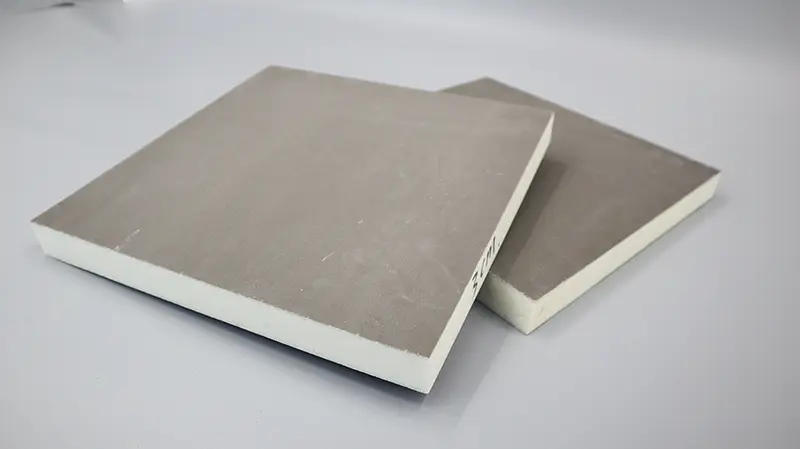

Правила энергоэффективности: Более строгие строительные нормы (например, IECC 2025) предписывают более высокие значения R, что делает полиизол (R-6,5/дюйм) лучшим выбором для крыш и стен.

Волна ретрофита: Государственные стимулы для энергоэффективной модернизации (например, Закон США о снижении инфляции) увеличили спрос на полиизол на 15% в 2025 году.

3. Производственные ограничения и проблемы с трудовыми ресурсами

Ограничения при производстве полиизола обусловлены нехваткой технических и кадровых ресурсов:

Комплексное производство: Полиизол требует точного соотношения химикатов и контролируемых условий. Модернизация производства для соответствия новым экологическим стандартам (например, использование пенообразователей с низким содержанием ПГП) замедлила выпуск продукции на 20%.

Нехватка квалифицированной рабочей силы: Изоляционная промышленность испытывает 12% дефицит квалифицированных монтажников, что приводит к задержкам в монтаже, которые сказываются на складских запасах.

Фрагментация мощностей: Только 60% мирового производства контролируется ведущими игроками (например, Owens Corning, BASF), что ограничивает масштабируемость при скачках спроса.

4. Региональные различия усиливают нехватку кадров

Региональная доступность Polyiso резко варьируется, создавая локальные кризисы:

| Регион | Степень нехватки | Ключевые драйверы | Инфляция цен |

|---|---|---|---|

| Северная Америка | Критический (дефицит 30%) | Высокий спрос на модернизацию, влияние тарифов | 35-40% г/г |

| Европа | Умеренный | Энергетический кризис, медленное восстановление сырьевой базы | 20-25% г/г |

| Азиатско-Тихоокеанский регион | Низкий (избыток в Китае) | Локализованное производство, слабая нормативная база | 10-15% г/г |

Северная Америка: Сильная зависимость от импорта + бурный рост строительства = острая нехватка.

Азиатско-Тихоокеанский регион: Самодостаточность Китая в производстве химикатов защищает его от дефицита, но логистика препятствует облегчению экспорта.

5. Стратегии смягчения последствий и адаптация промышленности

Решения по устранению дефицита полиизола появляются по всей цепочке создания стоимости:

Замена материала: Строители используют XPS или EPS там, где это возможно, хотя при этом происходит снижение R-значения.

Технологические инновации: Такие производители, как Kingspan, внедряют производство на основе искусственного интеллекта, чтобы оптимизировать использование сырья и сократить количество отходов на 15%.

Диверсификация цепочки поставок: Такие компании, как Dow, переносят производство в Бразилию и Индию, сокращая тарифную зависимость.

6. Перспективы на будущее: Когда ослабнет дефицит?

Прогноз развития рынка полиизола предполагает постепенное облегчение к 2026 году, в зависимости от:

Расширение мощностей: BASF и Honeywell планируют построить новые заводы в США к 2025 году, увеличив объем производства на 25%.

Прорывы в области переработки отходов: Инициативы по замкнутому циклу переработки (например, программа переработки полиизола) направлены на утилизацию 30% лома к 2027 году.

Поддержка политики: Ускоренное производство отечественного сырья (например, гранты США на добычу критических минералов) может снизить зависимость от импорта.

Совет профессионала: Для проектов с задержками заказывайте полиизол на 4-6 месяцев вперед и указывайте "выдержанное значение R-value", чтобы учесть тепловой разброс во время хранения.

Стратегическая адаптация к нехватке полиизола

Сайт дефицит полиизоляции это многогранный кризис, в основе которого лежат дисбаланс спроса и предложения, производственные трудности и геополитические трения. Хотя облегчение ситуации прогнозируется к 2026 году, заинтересованные стороны могут смягчить последствия, диверсифицируя материалы, используя технологии и выступая за политические реформы. По мере ужесточения требований к экологическому строительству полиизол остается критически важным материалом, но стратегическая гибкость позволит отделить жизнеспособные проекты от застопорившихся объектов.