L'isolation en polyisocyanurate (polyiso) est largement utilisée dans les toits, les murs et les sous-sols en raison de sa haute résistance à la corrosion. performance thermique (généralement R-6.0-R-6.5 par pouce). Mais une question persiste : Sa valeur R se dégrade-t-elle avec le temps ? La réponse tient à la chimie, à la température et aux pratiques d'installation.

La réponse courte

Polyiso ne subit pas de perte significative de valeur R à long terme dans des conditions normales. Cependant, deux facteurs peuvent provoquer réduction initiale et minimale:

Dérive thermique: Une légère baisse de la valeur R se produit lorsque les agents gonflants (gaz piégés dans les cellules lors de la fabrication) se diffusent. Ce phénomène se stabilise au bout de 1 à 2 ans.

Dépendance de la température: Valeur R du polyiso diminue temporairement lorsque la température moyenne à travers le matériau tombe en dessous de 40°F (4°C) .

Facteurs clés affectant la valeur R du polyiso

1. Sensibilité à la température

- En dessous de 4°C (40°F), la valeur R du polyiso diminue. En voici un exemple :

- À 25°F (-4°C), le polyiso R-6.0 peut avoir un rendement plus proche de R-5.5.

- A 0°F (-18°C), il peut descendre jusqu'à R-5.0.

- Au-dessus de 40°F, il offre une valeur R proche de celle indiquée sur l'étiquette.

- Pourquoi ? Les agents d'expansion hydrocarbonés de l'isolant se condensent à basse température, ce qui réduit leur résistance thermique.

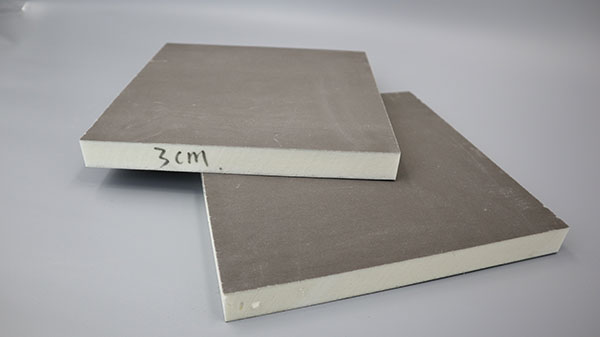

2. Scellement des bords et exposition à l'humidité

- Bords coupés exposés à l'humidité (par exemple, les dalles de sous-sol sans pare-vapeur) peuvent absorber de l'eau, ce qui réduit la valeur R. Les parements en feuille permettent d'atténuer ce phénomène. Les parements en feuille permettent d'atténuer ce phénomène.

- Polyiso non revêtu est vulnérable dans des conditions humides. Toujours sceller les bords dans les applications sous le niveau du sol.

3. Vieillissement ("dérive thermique")

- Après l'installation, le polyiso perd de sa valeur R 2-5% à mesure que les agents gonflants s'échappent, pour se stabiliser dans les 24 mois.

- Performances à long terme: La valeur R vieillie reste à 90-95% de la valeur étiquetée, comparable à celle du XPS et de l'EPS .

Polyiso vs. autres isolants : Stabilité de la valeur R

Tableau : Comparaison des performances des isolants dans le temps

| Matériau | Valeur R par pouce | Performance à froid | Impact du vieillissement (après 20 ans) |

|---|---|---|---|

| Polyiso | R-6.0-R-6.5 | Diminution en dessous de 40°F | Perte de ~5% (se stabilise) |

| XPS | R-5.0 | Stable | 10-20% perte |

| EPS | R-3.6-R-4.4 | Stable | <5% perte |

- Polyiso vs. XPS: Le XPS conserve mieux sa valeur R au froid, mais perd plus à long terme en raison de l'humidité. les gaz à potentiel de réchauffement planétaire (PRP) la diffusion .

- Polyiso vs. EPS: Le PSE est stable à la température mais offre une valeur R inférieure. Le polyiso est plus performant dans les climats chauds ou les applications intérieures.

Meilleures pratiques pour maximiser la valeur R du polyiso

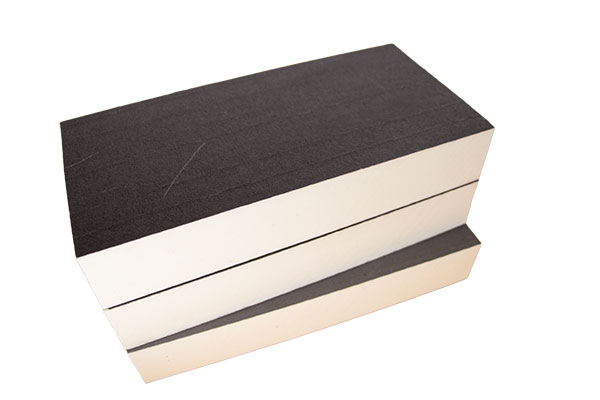

- Installation multicouche:

- Décaler les joints entre les couches pour réduire les ponts thermiques et les fuites d'air. Cela renforce également la durabilité.

- Utilisation dans des applications à des températures supérieures à 40°F:

- Idéal pour les murs intérieurs, les toits et les sous-sols climatisés. Éviter l'utilisation sous le niveau du sol à l'extérieur dans les climats froids.

- Sceller les bords et utiliser des pare-vapeur:

- Protéger les bords coupés avec du ruban adhésif ou des produits d'étanchéité. Installer sur un pare-vapeur dans les sous-sols.

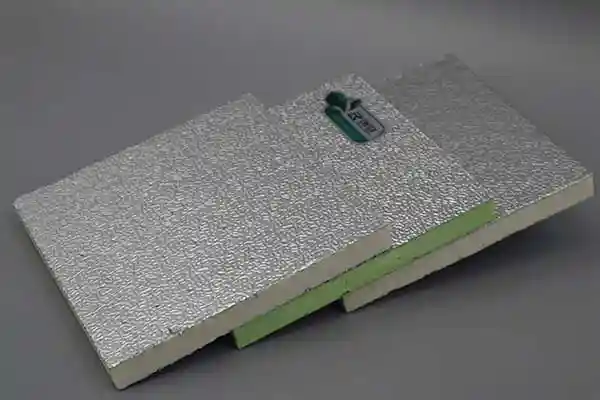

- Paire de planches de couverture:

- Les panneaux de couverture en polyiso haute densité (HD) ajoutent une résistance à la compression et maintiennent la valeur R dans les systèmes de toiture.

Le verdict

Valeur R du polyiso ne se dégrade pas de manière significative au fil des décennies s'il est installé correctement. Sa dérive thermique initiale est mineure (≤5%), et elle se stabilise après 2 ans. Alors que les températures froides réduisent sa à court terme il reste un choix de premier ordre pour les.. :

- Remplacement des toits (avec des planches de couverture coniques ou HD) .

- Murs au-dessus du niveau du sol et sous-sols conditionnés.

- Hiérarchisation des projets la durabilité (le polyiso utilise du pentane, un agent gonflant à faible PRG).

Pour les climats froids (<40°F), associer le polyiso à des isolants complémentaires (par exemple, EPS) ou augmenter l'épaisseur de 10-20% pour compenser les effets de la température.

💡 Conseil de pro: Toujours préciser valeur R âgée (non initiale) lors du calcul de la conformité au code de l'énergie. Les fabricants fournissent ces données sur demande.