El aislamiento de poliisocianurato (poliiso) se utiliza ampliamente en tejados, paredes y sótanos por su alto rendimiento. rendimiento térmico (normalmente R-6,0-R-6,5 por pulgada). Pero persiste una pregunta: ¿Se degrada su valor R con el tiempo? La respuesta tiene que ver con la química, la temperatura y las prácticas de instalación.

La respuesta breve

Poliiso no experimenta una pérdida significativa del valor R a largo plazo en condiciones normales. Sin embargo, dos factores pueden provocar reducción inicial mínima:

Deriva térmica: Se produce un ligero descenso del valor R a medida que los agentes expansivos (gases atrapados en las células durante la fabricación) se difunden hacia el exterior. Esto se estabiliza al cabo de 1-2 años.

Dependencia de la temperatura: Valor R de Polyiso disminuye temporalmente cuando la temperatura media a través del material desciende por debajo de 4°C (40°F) .

Factores clave que afectan al valor R del poliisocianurato

1. Sensibilidad a la temperatura

- Por debajo de 4°C (40°F), el valor R del poliisocianurato disminuye. Por ejemplo:

- A 25°F (-4°C), el poliisocianurato R-6.0 puede rendir más cerca de R-5.5.

- A 0°F (-18°C), puede descender a R-5,0.

- Por encima de 40°F, ofrece un valor R cercano al etiquetado.

- ¿Por qué? Los agentes espumantes de hidrocarburos del aislamiento se condensan a bajas temperaturas, lo que reduce su resistencia térmica .

2. Sellado de bordes y exposición a la humedad

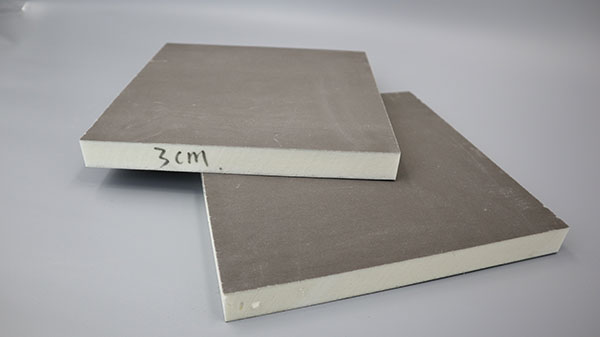

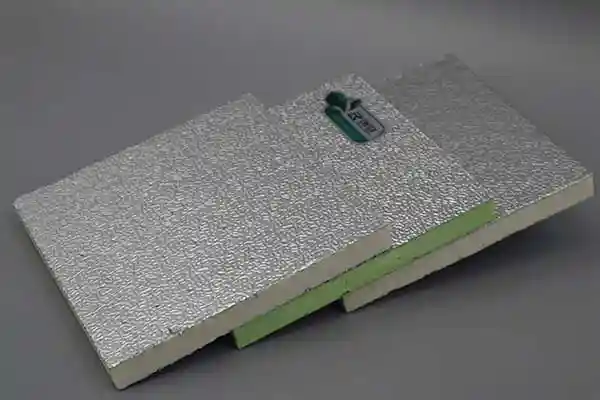

- Bordes cortados expuestos a la humedad (por ejemplo, losas de sótano sin barreras de vapor) pueden absorber agua, reduciendo el valor R. Los revestimientos de lámina mitigan este efecto.

- Poliiso sin revestimiento es vulnerable en condiciones de humedad. Selle siempre los bordes en aplicaciones bajo rasante.

3. Envejecimiento ("deriva térmica")

- Después de la instalación, el poliisocianato pierde valor R 2-5% a medida que se escapan los agentes espumantes, estabilizándose en 24 meses.

- Resultados a largo plazo: El valor R envejecido sigue siendo 90-95% del valor etiquetado, comparable al XPS y EPS .

Poliiso frente a otros aislamientos: Estabilidad del valor R

Tabla: Comparación del rendimiento del aislamiento a lo largo del tiempo

| Material | Valor R por pulgada | Rendimiento en frío | Impacto del envejecimiento (después de 20 años) |

|---|---|---|---|

| Poliiso | R-6.0-R-6.5 | Disminuye por debajo de 40°F | ~5% de pérdida (se estabiliza) |

| XPS | R-5.0 | Estable | Pérdida 10-20% |

| EPS | R-3.6-R-4.4 | Estable | <5% pérdida |

- Polyiso vs. XPS: El XPS mantiene mejor el valor R en frío pero pierde más a largo plazo debido al gases con potencial de calentamiento global (PCG) difusión .

- Poliiso vs. EPS: El EPS es estable a la temperatura pero ofrece un valor R inferior. El poliisocianurato lo supera en climas cálidos o aplicaciones interiores.

Prácticas recomendadas para maximizar el valor R del poliisocianurato

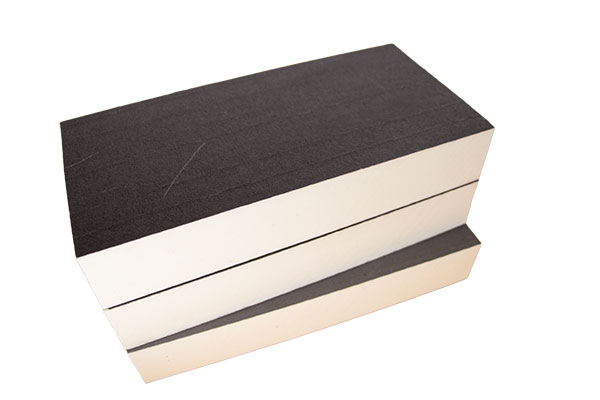

- Instalación multicapa:

- Escalone las juntas entre las capas para reducir los puentes térmicos y las fugas de aire. Esto también aumenta la durabilidad.

- Uso en aplicaciones por encima de 40 °F:

- Ideal para paredes interiores, tejados y sótanos acondicionados. Evitar su uso en exteriores bajo rasante en climas fríos.

- Sellado de bordes y barreras de vapor:

- Proteja los bordes cortados con cinta de aluminio o selladores. Instalar sobre una barrera de vapor en sótanos .

- Pareja con tableros de cubierta:

- Las placas de cubierta de poliisocianurato de alta densidad (HD) añaden resistencia a la compresión y mantienen el valor R en los sistemas de cubiertas .

El veredicto

Valor R del poliisocianurato no se degrada significativamente durante décadas si se instala correctamente. Su deriva térmica inicial es menor (≤5%), y se estabiliza al cabo de 2 años. Aunque las temperaturas frías reducen su a corto plazo eficiencia, sigue siendo una opción de primer orden para:

- Sustitución de tejados (con tablas de cubierta cónicas o HD) .

- Paredes sobre rasante y sótanos acondicionados.

- Priorización de proyectos sostenibilidad (el poliisocianurato utiliza pentano, un agente espumante de bajo PCA).

Para climas fríos (<40 °F), combine el poliiso con aislamientos complementarios (por ejemplo, EPS) o aumente el espesor en 10-20% para compensar los efectos de la temperatura.

💡 Consejo profesional: Especifique siempre valor R envejecido (no inicial) al calcular el cumplimiento del código energético. Los fabricantes facilitan estos datos previa solicitud.