When choosing insulation for a building project, R-value measures resistance to heat flow — and higher values mean better thermal performance. Among foam board types, PIR (poliisocianurato) consistently delivers the highest R-value per inch, typically ranging from R-6.0 to R-7.0 per inch, outperforming other common rigid foams37. This makes it the top choice for energy-efficient walls, roofs, and foundations where space is limited but high thermal resistance is critical.

Why R-Value Matters in Foam Board Insulation

R-value quantifies how effectively insulation resists heat transfer. Higher R-values mean:

- Greater energy savings due to reduced heating/cooling loads.

- Thinner insulation layers—vital for space-constrained applications like walls or attics.

- Long-term thermal stability when properly installed, preventing “thermal drift” (loss of R-value over time).

Foam boards dominate high-R applications due to their closed-cell structures, which trap insulating gas better than fibrous or open-cell materials.

PIR (Polyisocyanurate) Foam: The Highest R-Value Leader

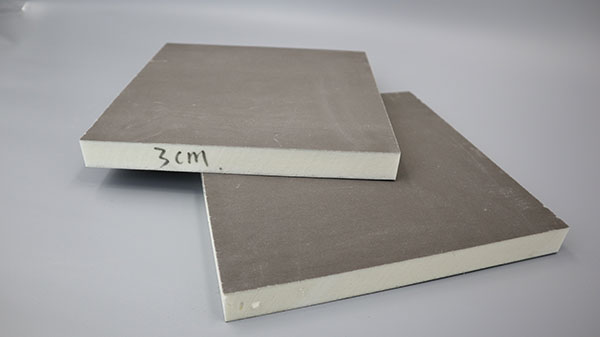

PIR foam boards deliver R-6.0–R-7.0 per inch, the highest rating among rigid foams. This stems from its low thermal conductivity (as low as 0.023 W/mK) y gas-filled closed-cell structure. Key features include:

- Foil facers that act as radiant barriers, boosting overall R-value by reflecting heat.

- Fire resistance due to self-extinguishing properties (typically Class B or Class 0 fire ratings).

- Moisture resistance, making it suitable for roofs, exterior walls (ETICS systems), and below-grade applications.

- Thinner installations—achieving R-30 requires just 5 inches of PIR vs. 10 inches of fiberglass.

Common uses: commercial roofing, cavity walls, and thermal bridge correction.

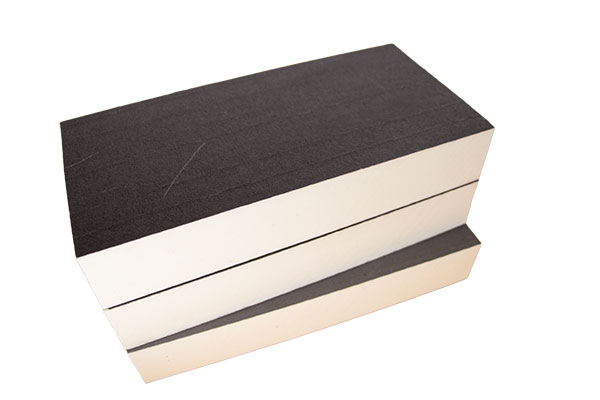

XPS (Extruded Polystyrene) Foam: Moisture-Resistant Performer

XPS offers R-5.0 per inch and excels in wet or high-load environments. Distinguishing traits:

- High compressive strength (up to 800 kPa), ideal for foundations, tank bases, and green roofs.

- Minimal water absorption (<0.3%), maintaining R-value in damp conditions.

- Smooth surface allows easy installation of membranes or finishes.

Limitation: R-value can drop by ~10% over time as blowing gases escape.

EPS (Expanded Polystyrene) Foam: Cost-Effective All-Rounder

Standard EPS provides R-3.6–R-4.2 per inch, but graphite-enhanced EPS reaches R-4.5–R-5.0 by reflecting heat. Advantages:

- Lower cost than PIR or XPS.

- Versatility—used in walls, foundations (e.g., Insulfoam DB drainage board), and under slabs.

- Long-term stability—no significant thermal drift.

Spray Polyurethane Foam (SPF): High Performance in Cavities

While not a rigid “board,” SPF deserves mention:

- Closed-cell SPF provides R-6.0–R-7.0 per inch, matching PIR.

- Seals air leaks completely, adding structural strength.

- Ideal for irregular shapes (e.g., attic rafters, rim joists).

Specialty Foams: Niche High-R Options

- Foamglass (FOAMGLAS®): R-3.3 per inch but non-combustible and impermeable, used in industrial settings like LNG tank bases.

- PE Foam Sleep Pads: For outdoor use, PIR-based mats achieve R-2.1–R-2.2 (tested via ASTM F3340-18)9—highest among portable foams.

Comparing R-Values: Key Data at a Glance

Table: Rigid Foam Board R-Values and Applications

| Foam Type | R-Value per Inch | Best For | Limitations |

|---|---|---|---|

| PIR | R-6.0–R-7.0 | Roofs, walls, energy-critical zones | Higher cost |

| XPS | R-5.0 | Foundations, below-grade, wet areas | R-value degrades slightly |

| Graphite EPS | R-4.5–R-5.0 | Budget projects, foundations | Lower compressive strength |

| Standard EPS | R-3.6–R-4.2 | General use, packaging | Not for high-load areas |

Key Factors Beyond R-Value

Choosing foam isn’t just about R/in:

- Climate: Cold regions (e.g., northern U.S.) need attic R-values of R-49–R-60; moderate zones require R-30–R-385.

- Moisture: Use XPS or closed-cell foam in basements.

- Fire Codes: PIR and spray foam often meet stricter building standards.

- Coste: PIR costs ~20% more than XPS but offers 15–20% higher R-value.

For the absolute highest R-value in foam board insulation, PIR (polyiso) is the undisputed leader at R-7.0 per inch. Combine it with an aluminum foil facer for an additional radiant barrier effect. In moisture-prone or load-bearing scenarios, XPS or graphite EPS are practical alternatives. Always verify local building codes and third-party certifications (ISO 9001, ASTM) when selecting boards.