Al especificar el aislamiento para proyectos comerciales o residenciales, la seguridad contra incendios no es negociable. Los paneles de PIR (poliisocianurato) son uno de los principales competidores en eficiencia térmica, pero su comportamiento frente al fuego suele condicionar las decisiones finales. Dejemos a un lado el ruido: El PIR no es ignífugopero su resistencia al fuego supera la de la mayoría de las espumas alternativas. Esto es lo que deben entender los profesionales.

Clasificación de incendios: Dónde se sitúa PIR

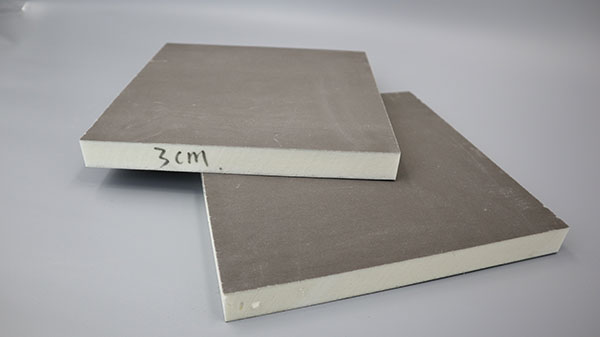

Las placas PIR suelen alcanzar un Euroclase B-s1, d0 según la norma EN 13501-1. Esto significa:

- Clase B: Combustible pero resistente a la ignición. A diferencia del EPS (Clase E) o el XPS (Clase F), el PIR no favorece la propagación rápida de la llama.

- s1: Emisión mínima de humo durante la combustión. Fundamental para una evacuación segura y para reducir la exposición tóxica.

- d0: Cero gotas inflamadas. Elimina los riesgos secundarios de incendio por restos fundidos.

Por ejemplo, la lana mineral es incombustible. Clase A1 rating. Sin embargo, el equilibrio del valor de aislamiento del PIR (lambda tan bajo como 0,022 W/mK) y el comportamiento ante el fuego lo convierten en una opción pragmática en muchos escenarios.

Cómo reacciona PIR bajo el fuego

Aunque ninguna espuma es totalmente ignífuga, la química del PIR le confiere una ventaja:

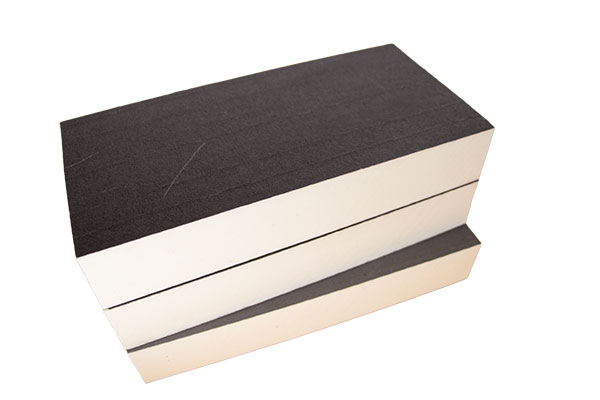

- Formación del carbón: Cuando se expone a una llama, la superficie del PIR se carboniza, creando una capa protectora que ralentiza la penetración del calor.

- Autoextinguible: Una vez eliminada la fuente de ignición, las llamas suelen extinguirse en cuestión de segundos.

- Baja toxicidad del humo: A diferencia del poliestireno en combustión, el PIR emite menos gases corrosivos como el cianuro de hidrógeno.

Aplicaciones probadas sobre el terreno

El comportamiento al fuego de PIR ha sido validado en ensamblajes del mundo real:

- Revestimientos pluviales: Combinado con cortafuegos y barreras de lana mineral, el PIR cumple las estrictas normas de seguridad de las fachadas (por ejemplo, la BR135 del Reino Unido).

- Cubiertas planas: Los sistemas que utilizan PIR con revestimientos de fibra de vidrio alcanzan clasificaciones BROOF(t4), adecuadas para edificios de alto riesgo.

- Compartimentación: Cuando se utiliza con placas ignífugas (por ejemplo, Gyproc FireLine), PIR mantiene la integridad del compartimento hasta 60 minutos.

Mejora del rendimiento contra incendios

Los detalles inteligentes amplifican la resistencia inherente del PIR:

- Tableros de barrera: La placa de yeso ignífugo de 12,5 mm añade Más de 30 minutos de protección.

- Sellantes intumescentes: Se expande con el calor para sellar los huecos alrededor de las instalaciones PIR.

- Sistemas híbridos: La superposición de PIR con lana mineral en configuraciones escalonadas equilibra los valores U y la seguridad contra incendios.

Las certificaciones importan

Verifique siempre las pruebas de terceros. Los fabricantes de PIR de buena reputación proporcionan:

- Marcado CE con informes EXAP que confirman la clase de reacción al fuego.

- ISO 1716 cumplimiento de la no combustibilidad de los materiales de revestimiento.

- Datos de pruebas a gran escala (por ejemplo, BS 8414 para fachadas).

Lo esencial

Los paneles PIR no son ignífugos, pero su resistencia al fuego satisface la mayoría de las exigencias normativas cuando se especifican correctamente. Para los proyectos que requieren soluciones incombustibles, la lana mineral sigue siendo la reina. Sin embargo, cuando la eficiencia térmica y el ahorro de espacio son prioritarios -especialmente en la rehabilitación o en las construcciones de paredes delgadas-, la lana mineral sigue siendo la mejor solución. PIR ofrece un equilibrio práctico y conforme a las normas.

Consulte siempre las garantías del sistema y los códigos locales. Los principales fabricantes, como Kingspan, Celotex y Recticel, ofrecen asistencia técnica para adaptar las soluciones PIR a sus requisitos de seguridad contra incendios.

Enfoque Palabras clave: Tableros PIR ignífugos, resistencia al fuego PIR, Euroclase B-s1 d0, aislamiento seguridad contra incendios

Descripción Meta: Los paneles PIR no son ignífugos, pero alcanzan la clasificación Euroclase B-s1,d0. Descubra cómo sus propiedades autoextinguibles y de formación de carbonilla cumplen los códigos de construcción cuando se especifican correctamente.