Espuma de poliisocianurato (PIR) es una espuma plástica termoestable de célula cerrada formada por la reacción exotérmica entre poliisocianatos y polioles. Su estructura molecular única -caracterizada por una alta concentración de anillos de isocianurato termoestables- le confiere unas propiedades de aislamiento térmico y una resistencia al fuego superiores a las de las espumas de poliuretano (PUR) estándar. Desarrollada en la década de 1960, la espuma PIR se ha convertido en un material fundamental en la construcción, el transporte de GNL, la industria aeroespacial y el aislamiento industrial debido a su capacidad para funcionar entre -196°C y +150°C manteniendo la integridad estructural .

Propiedades principales y métricas de rendimiento

La arquitectura molecular de la espuma PIR permite una combinación de propiedades físicas y térmicas incomparable con las espumas rígidas convencionales.

Rendimiento térmico

Baja conductividad térmica: Las muestras de espuma PIR fresca presentan valores de conductividad térmica tan bajos como 0,019 W/(m-K)que se mantiene estable a lo largo del tiempo (muestras envejecidas: ≤0,0218 W/(m-K)). Esto supera a las espumas PUR y a la lana mineral .

Alto valor R: El valor R (resistencia térmica por pulgada) del PIR suele oscilar entre R-6.0 y R-7.0lo que lo convierte en uno de los materiales aislantes más eficaces que existen.

Amplia temperatura de servicio: El PIR conserva sus propiedades a temperaturas extremas, desde condiciones criogénicas (-196°C) en el almacenamiento de GNL a +150°C en aplicaciones de techado .

Resistencia mecánica

Resistencia a la compresión: A temperatura ambiente, la espuma de PIR soporta una resistencia a la compresión de ≥200 kPa con una deformación de 10%. Tras sumergirla en nitrógeno líquido (-196 °C) durante 8 horas, esta resistencia aumenta hasta ≥280 kPa, lo que demuestra su fiabilidad en entornos criogénicos.

Estabilidad dimensional: La dilatación térmica lineal es mínima (≤70×10-⁶ m/m-K), lo que evita el alabeo o la contracción durante las fluctuaciones de temperatura .

Resistencia al fuego y seguridad

Propagación de la llama: PIR alcanza un índice máximo de propagación de la llama de <25, cumpliendo los B1 resistencia al fuego (según la norma GB8264) y reducir la generación de humo .

Índice de oxígeno: Con un índice de oxígeno ≥26, el PIR se autoextingue cuando se elimina la fuente de ignición .

Baja toxicidad: A diferencia de las primeras espumas PUR, las modernas formulaciones PIR minimizan los subproductos tóxicos, como las aminas aromáticas, mediante un curado optimizado .

Durabilidad medioambiental

Resistencia al agua: La absorción de agua se limita a ≤5%y su estructura de células cerradas limita la permeabilidad al vapor (≤0,8 g/m²).

Estabilidad química: Resiste la corrosión, el moho y los disolventes gracias a su matriz polimérica inerte.

Proceso de fabricación: Química y producción

Materias primas

Isocianatos: El diisocianato de metileno difenilo (MDI) es el componente principal debido a su reactividad y estabilidad térmica.

Polioles: Los polioles derivados del petróleo (número OH >200) o las alternativas de origen biológico (por ejemplo, los polioles derivados del aceite de colza) actúan como co-reactivos .

Catalizadores: El acetato de potasio o las sales de amonio cuaternario impulsan el reacción de trimerización del isocianuratoformando estructuras anulares robustas.

Agentes de soplado: El agua reacciona con los isocianatos para generar CO₂, aunque cada vez se utilizan más hidrofluoroolefinas (HFO) de bajo PCA.

Mecanismo de reacción

La síntesis PIR depende de la reacción de trimerizacióndonde tres grupos isocianato (NCO) ciclan en anillos isocianurato. Esta reacción domina sobre la formación de uretano (conversión >70%) cuando se optimizan los catalizadores. La estructura resultante contiene enlaces de uretano, urea, biuret e isocianurato .

Métodos de producción

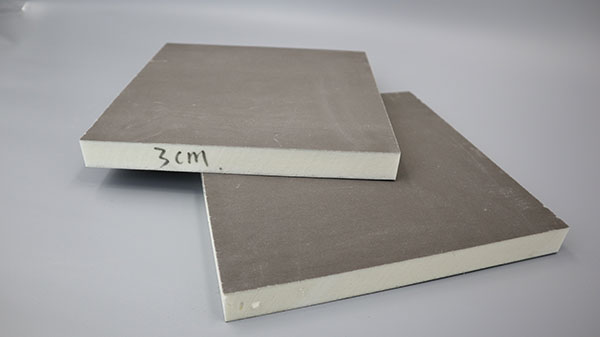

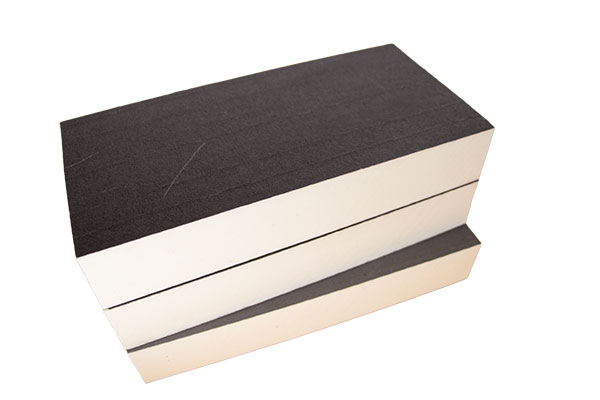

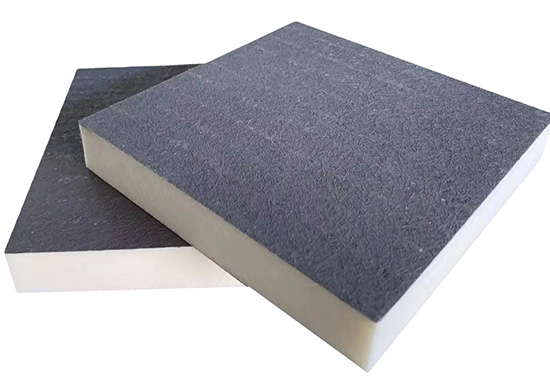

Laminación continua: Para paneles aislantesLos productos químicos se mezclan, se depositan sobre los revestimientos (por ejemplo, papel de aluminio) y se curan en un horno de doble cinta transportadora. Los sensores de temperatura controlan el aumento de la espuma (140-160°C) para garantizar la calidad.

Espuma en Spray/Pour: Para aplicaciones in situ (por ejemplo, tejados o tanques de GNL), un sistema de pulverización de dos componentes proporciona espuma que se expande y cura en cuestión de segundos. Las fórmulas desarrolladas por la NASA para los tanques de los transbordadores espaciales utilizaban espuma vertida para adherirse al aluminio a temperaturas criogénicas .

Producción por lotes: Las formas personalizadas se crean vertiendo espuma en moldes, seguida de un curado en horno.

Innovaciones ecológicas

Bio-Polioles: Los polioles a base de aceite de colza sintetizados mediante epoxidación o transesterificación reducen la dependencia de los combustibles fósiles .

Modificadores ignífugos: El grafito expandible (3-9 wt.%) mejora la resistencia al fuego sin aditivos halogenados .

Aplicaciones en todos los sectores

Edificación y construcción

Los paneles PIR dominan el aislamiento de cubiertas planas y paredes gracias a su alto valor R y a su seguridad contra incendios. Los espesores se cortan con CNC para una mayor precisión y minimizar los puentes térmicos.

Aislamiento criogénico industrial

Los gasoductos y tanques de almacenamiento de gas natural licuado (-196 °C) confían en el PIR por su estabilidad térmica y su resistencia a la compresión en condiciones de nitrógeno líquido.

Aeroespacial y usos especializados

Los tanques externos del transbordador espacial de la NASA Espuma vertida PIR como protección térmica. Las formulaciones recientes mejoran la adherencia al aluminio y el rendimiento criogénico .

Poliisocianurato frente a espuma de poliuretano: Diferencias críticas

Aunque ambos son aislantes aplicados por pulverización o en placas, la estructura molecular del PIR ofrece ventajas distintas:

Tabla: Comparación del rendimiento de PIR frente a PUR

| Propiedad | Espuma PIR | Espuma PUR |

|---|---|---|

| Conductividad térmica | 0,019-0,022 W/(m-K) | 0,022-0,025 W/(m-K) |

| Temperatura de servicio | -196°C a +150°C | -50°C a +120°C |

| Resistencia a la compresión | ≥200-280 kPa | 100-150 kPa |

| Resistencia al fuego | Clasificación B1, Índice de oxígeno ≥26 | Clasificación B2, Índice de oxígeno ~22 |

| Coste típico | 10-15% superior | Menor coste básico |

Tabla: Especificaciones técnicas de la espuma PIR (según las normas del sector)

| Parámetro | Unidad | Valor |

|---|---|---|

| Densidad | kg/m³ | ≥35 |

| Conductividad térmica | W/(m-K) | ≤0.019 (fresco) |

| Resistencia a la compresión | kPa | ≥200 (ambiente) |

| Índice de oxígeno | - | ≥26 |

| Absorción de agua | % | ≤5 |

| Contenido en cloruro | ppm | ≤60 |

Espuma de poliisocianurato marca la referencia en aislamiento termoestable rígido gracias a su mezcla de conductividad térmica ultrabaja, excepcional resistencia al fuegoy durabilidad mecánica. Las innovaciones en materias primas de origen biológico y agentes espumantes con bajo potencial de calentamiento global están mejorando su perfil de sostenibilidad, mientras que los avances en la fabricación garantizan la precisión en aplicaciones de alto riesgo, desde la infraestructura de GNL hasta la industria aeroespacial. Aunque es más caro que el PUR, la eficiencia de su ciclo de vida y su seguridad justifican la inversión para la gestión térmica crítica.