PIR (Polyisocyanurate) foam is widely used as an insulation material in buildings, pipes, and cold storage due to its excellent thermal performance. However, like any material, PIR insulation has several drawbacks. Understanding these negatives of PIR insulation helps builders, architects, and homeowners make informed decisions about whether it’s the right choice for their projects. This article explores the key problems associated with PIR, including fire safety risks, installation challenges, environmental impacts, durability concerns, and higher costs.

Fire Safety: Not Completely Fireproof

While PIR is often marketed as having good fire resistance compared to materials like EPS or XPS, it’s not non-combustible.

Fire Risk: PIR can ignite and burn when exposed to direct flames or high heat. Tests show that although it may char or carbonize instead of melting like some plastics, it still contributes to fire spread under intense conditions.

Toxic Smoke: When burning, PIR releases dense, toxic smoke containing dangerous gases like cyanide (hydrogen cyanide) and carbon monoxide. These gases pose serious inhalation risks during fires and are often more deadly than the flames themselves.

Building Code Limits: Many countries restrict PIR use in tall buildings. For example, Germany bans organic insulation like PIR on structures over 22 meters, while the UK sets the limit at 18 meters5. Fire barriers (isolation belts) are required by codes like China’s GB50016 to slow vertical fire spread.

Installation and Handling Challenges

PIR insulation problems often appear during installation due to its physical properties:

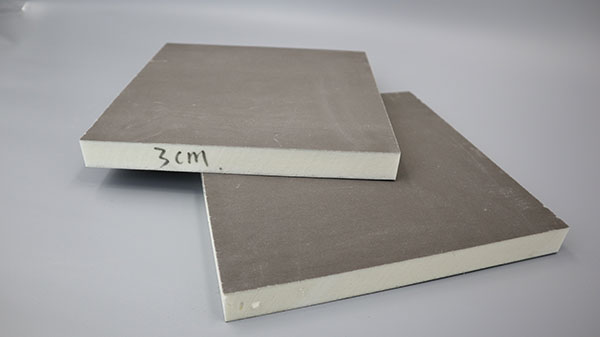

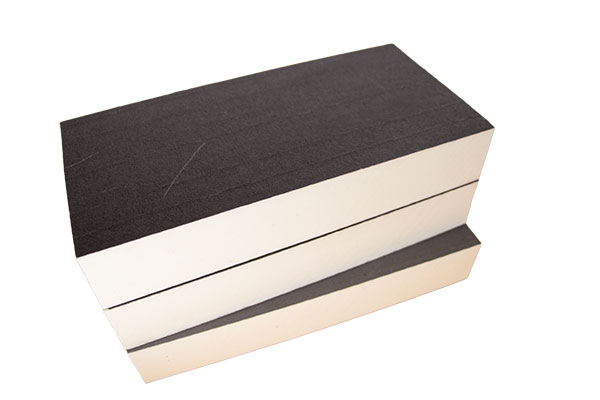

Brittleness: PIR panels are relatively stiff and brittle. They can crack or break if bent or handled roughly, especially in cold weather. This makes them harder to fit tightly around pipes or curved surfaces.

Poor Adhesion: Unlike PUR (polyurethane), PIR bonds weakly to surfaces. Its adhesion strength is roughly half that of PUR, requiring extra adhesives or mechanical fasteners to stay securely attached. Gaps or loose sections can form, reducing thermal efficiency.

Temperature Sensitivity: PIR production needs precise temperature control (above 60°C). Small changes can cause defects like surface bubbles, uneven curing, or shrinkage.

Environmental and Durability Concerns

Though long-lasting, PIR isn’t immune to aging and environmental damage:

Moisture Absorption: PIR can absorb water over time, especially if the protective foil or coating gets damaged. Wet insulation loses its thermal performance (R-value) and promotes mold growth, which releases unhealthy spores.

Material Degradation: PIR foam gradually breaks down (“ages”), becoming brittle and less effective. Insulation in buildings should ideally last 50+ years, but PIR may deteriorate in 20–30 years, requiring replacement and adding long-term waste.

Recycling Difficulty: Most PIR ends up in landfills after removal because it’s hard to recycle. Burning it releases toxic fumes, creating disposal challenges.

Cost and Availability Issues

PIR insulation cost is higher than alternatives:

Expensive Raw Materials: PIR relies on MDI (a type of isocyanate), which is costly and sometimes hard to source. This makes PIR pricier than materials like EPS or mineral wool.

Thicker Layers Needed: In cold applications, PIR is sometimes paired with foam glass due to its lower low-temperature stability. Though PIR has good insulation value, alternatives like foam glass might require similar thicknesses for equal performance but last longer without degrading.

Balancing the Negatives: Best Practices

Despite these drawbacks, PIR remains popular for its high insulation value. To use it more safely and effectively:

Follow Fire Codes: Always install non-combustible fire breaks (e.g., mineral wool strips) every floor level as per regulations.

Add Protective Layers: Cover PIR with fire-resistant coatings or boards (e.g., cement board or fire-rated gypsum) to slow ignition and limit toxic smoke.

Ensure Quality Installation: Hire experienced installers to avoid gaps, cracks, or moisture traps. Use compatible adhesives/sealants for better bonding.

Consider Alternatives: Where fire safety is critical (high-rises, hospitals), evaluate non-combustible options like rock wool or phenolic foam.

PIR insulation offers excellent thermal efficiency but comes with significant downsides—fire risks, tricky installation, moisture sensitivity, and higher costs. Understanding these negatives of PIR insulation helps users plan safer, longer-lasting projects. Always prioritize fire barriers and protective covers, follow local building codes, and consider the total lifecycle impact when choosing insulation materials.