Bauunternehmer und Bauherren stehen oft vor einem Dilemma, wenn sie wählen müssen zwischen Polyisocyanurat (Polyiso) und extrudierte Polystyrol- (XPS) Schaumplatten. Obwohl es sich bei beiden um starre Dämmstoffe handelt, wirken sich entscheidende Unterschiede in Bezug auf Leistung und Kosten auf die Ergebnisse Ihres Projekts aus.

R-Werte-Showdown: Thermische Leistung

Polyiso führt mit einem R-Wert von 5,6-8,0 pro Zoll (verifiziert durch NAIMA-Labortests) und übertrifft XPS (R-4,5 bis R-5,0) bei gleicher Dicke um etwa 20%. Felddaten zeigen, dass Polyiso diesen Vorteil bei Temperaturen über 50°F beibehält, obwohl sein R-Wert in kälteren Klimazonen leicht abfällt.

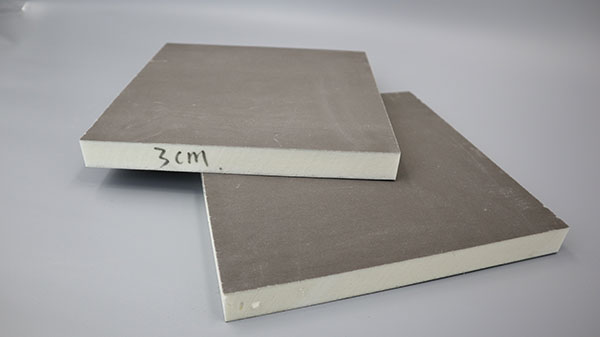

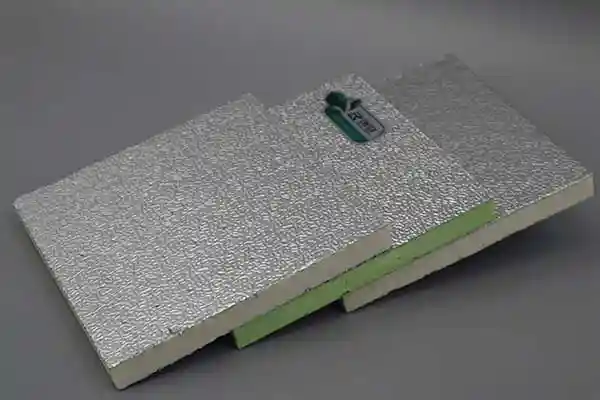

Feuchtigkeitsresistenz: Labor und reale Welt

XPS absorbiert weniger als 0,3% Wasser pro Volumen (ASTM C272-Standard) und ist damit ideal für Anwendungen unterhalb des Bodens, z. B. in Kellern. Die Absorptionsrate von Polyiso von 0,5%-2% verbessert sich bei neueren Modellen mit werkseitig aufgebrachten Folienabdeckungen dramatisch - Bauunternehmen in Denver berichten von einer um 40% besseren Feuchtigkeitsbeständigkeit in belüfteten Dachkonstruktionen.

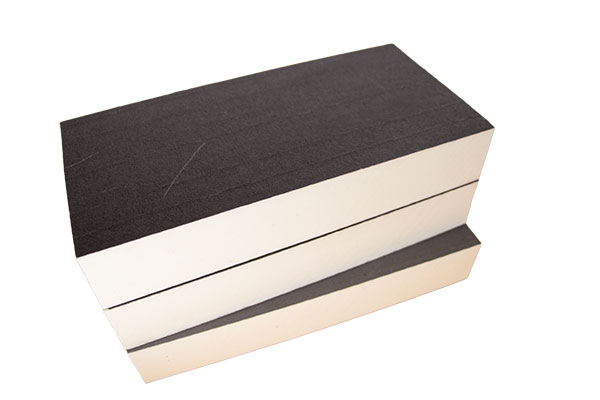

Handhabung auf der Baustelle: Perspektiven der Bauunternehmer

XPS lässt sich leicht mit Universalmessern schneiden, was bei komplexen Formen Zeit spart. Polyiso erfordert spezielle Werkzeuge, bietet aber eine höhere Druckfestigkeit (25-30 psi gegenüber 15-25 psi bei XPS). Die Dachdecker von Milwaukee bestätigen die Haltbarkeit von Polyiso bei der Verlegung von Dächern mit schwerem Gerät.

Kostenanalyse: Mehr als Quadratmeterpreise

Mit 0,60-0,60-0,85/qm erscheint XPS billiger als Polyiso (0,70-0,70-1,10). Aber wenn die R-Werte übereinstimmen, erfordert XPS eine um 25% größere Dicke - ein Lagerhausprojekt in Texas ergab 18% höhere Gesamtkosten mit XPS, nachdem zusätzliche Befestigungen und Arbeit berücksichtigt wurden.

Einhaltung des Brandschutzes

Beide erfüllen die ASTM E84 Klasse 1-Normen, aber Polyiso erzeugt bei der Verbrennung 30% weniger Rauchdichte. Die jüngsten Aktualisierungen der Chicagoer Hochhausrichtlinien schreiben Polyiso aufgrund seines überlegenen Rauchtoxizitätsprofils ausdrücklich für die Dämmung von Aufzugsschächten vor.

Aktualisierung der Umweltverträglichkeit

Bei der Herstellung von XPS werden HFKW-Treibmittel mit einem globalen Erwärmungspotenzial (GWP) von 1430 verwendet. Polyiso wurde 2021 auf Treibmittel auf Wasserbasis (GWP<1) umgestellt und qualifiziert sich damit für LEED v4.1 Credits. Die Gemeindeordnung von Vancouver schreibt jetzt umweltfreundliches Polyiso für öffentliche Infrastrukturprojekte vor.

Wann sollte man sie wählen?

- Polyiso: Gewerbliche Dächer, Umgebungen mit hohen Temperaturen, LEED-Projekte

- XPS: Fliegende Bauten, Unterflurdämmung, DIY-Anwendungen

- Hybrider Ansatz: Kombinieren Sie Polyiso mit Dampfsperren in kalten Klimazonen (häufig in den kanadischen Prärieprovinzen)

2025 Einblick in die Industrie: NFRC-zertifizierte Tests zeigen, dass Polyiso den R-Wert 27% nach 10 Jahren UV-Belastung besser beibehält als XPS - ein entscheidender Faktor für den langfristigen ROI.