Extruded Polystyrene (XPS) foam is a rigid insulation material widely used in construction for its moisture resistance and compressive strength. However, like any material, it has notable drawbacks that architects, builders, and homeowners should consider. This article objectively examines the key disadvantages of XPS foam, providing insights to help you make informed insulation decisions.

Understanding XPS Foam and Its Key Drawbacks

XPS foam is a type of plastic insulation produced by extruding polystyrene through a die. While valued for its closed-cell structure and immediate thermal performance, it faces criticism in several areas:

- Environmental Impact: Traditional XPS is manufactured using blowing agents with high Global Warming Potential (GWP). Although newer formulations aim to be more eco-friendly, legacy and some current products still contribute significantly to greenhouse gas emissions over their lifecycle.

- Long-Term Thermal Performance: Some studies indicate that the thermal resistance (R-value) of XPS can decrease over time as the blowing agents diffuse out and air diffuses in—a process called “thermal drift.”

- Cost vs. Performance: While not always the most expensive, XPS often comes at a higher cost per R-value compared to some alternative insulations like polyurethane foam or mineral wool, especially when considering long-term efficiency.

- Recyclability Challenges: XPS is difficult to recycle efficiently at end-of-life. It often ends up in landfills, adding to plastic waste concerns.

- Chemical Sensitivity: XPS can be degraded by certain solvents, petroleum-based products, and prolonged UV exposure if not properly protected.

Common Questions About XPS Foam Disadvantages

Q1: Is XPS foam really bad for the environment?

A1: It depends on the specific product and perspective. Historically, XPS relied on HFC blowing agents with very high GWP. Many manufacturers now use lower-GWP alternatives, but the overall environmental footprint—from petroleum-based raw materials to low recyclability—remains a concern compared to bio-based or more easily recycled insulations.

Q2: Does XPS insulation lose its R-value over time?

A2: Yes, like many closed-cell foam insulations, XPS can experience thermal drift. The initial R-value is typically rated between R-4.5 and R-5 per inch, but this may slightly decrease over decades as gases within the cells equilibrate with the air. Proper product selection and installation can mitigate, but not eliminate, this effect.

Benefits of Understanding These Disadvantages

Recognizing the limitations of XPS foam allows you to:

- Make better, more sustainable insulation choices aligned with project goals and environmental values.

- Plan for long-term building performance rather than just initial costs.

- Comply more effectively with green building standards (e.g., LEED, BREEAM) by selecting lower-impact materials.

- Avoid potential moisture or degradation issues by understanding material compatibility.

How to Evaluate and Choose Insulation Responsibly

Follow these steps to select the right insulation for your needs:

Define Your Priorities

Identify what matters most: upfront cost, lifetime performance, environmental impact, fire resistance, or moisture control.

Compare Materials Objectively

Create a comparison table for XPS, mousse de polyuréthane (PIR/PUR), mineral wool, EPS, and other relevant options. Compare R-value per inch, cost, GWP of blowing agents, recyclability, and durability.

Check Certifications and Data

Look for Environmental Product Declarations (EPDs), GREENGUARD, or other third-party certifications. Verify long-term thermal resistance (LTTR) values for foam plastics.

Consider the Whole System

Evaluate how the insulation works with adjacent materials (vapor barriers, cladding, etc.) to avoid compatibility issues.

Consult with Professionals

Engage architects, engineers, or insulation specialists who have hands-on experience with multiple materials in applications similar to yours.

Real-World Outcomes of Informed Insulation Choices

Commercial Retrofit Project

A property developer initially specified XPS for a roof renovation. After reviewing EPDs and lifetime cost analysis, they switched to polyurethane-based insulation (PIR). This provided a higher Valeur R per inch and lower thermal drift, reducing the required thickness. The project achieved better energy performance and a lower calculated carbon footprint for the insulation layer.

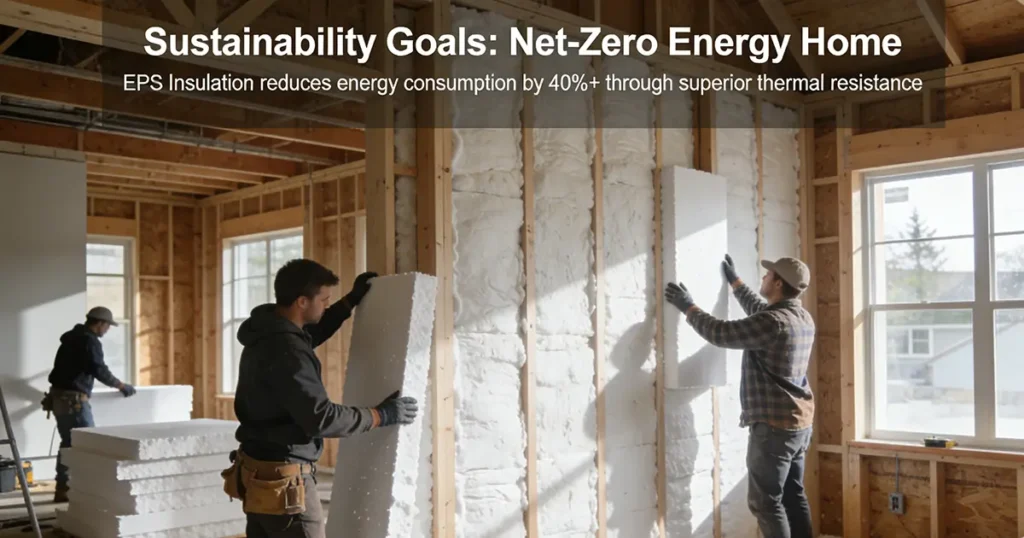

Residential Net-Zero Home

A builder aiming for Passive House certification compared XPS to expanded polystyrene (EPS) for below-slab insulation. While XPS offered higher moisture resistance, the EPS selected had a significantly lower GWP and was available with recycled content. Combined with a robust moisture protection layer, the EPS met performance requirements while aligning with the project’s sustainability goals.

Industrial Cold Storage Facility

The engineering team needed insulation with stable long-term R-value and low water absorption. They evaluated aged R-value data and chose a premium XPS type with third-party verified LTTR values. However, for certain sections, they supplemented with polyurethane foam where higher R-value and dimensional stability were critical, demonstrating a hybrid approach based on specific performance needs.

As an insulation manufacturer with years of industry experience, we believe transparent, evidence-based information is crucial for our clients. While XPS foam has its applications, understanding its limitations empowers better building decisions. We recommend always consulting recent technical data and considering the full lifecycle performance of any insulation material.