El aislamiento de poliisocianurato se utiliza ampliamente en la construcción por su alta resistencia térmica (valor R) y su eficiencia energética. Sin embargo, la cuestión de su rendimiento a largo plazo, en concreto si el poliisocianurato pierde valor R con el tiempo, sigue siendo una preocupación fundamental para constructores, arquitectos y propietarios de viviendas. Este artículo examina los factores que influyen en la estabilidad del valor R del poliisocianurato, apoyándose en datos de investigación y de la industria, al tiempo que aborda las preocupaciones relacionadas con la durabilidad del aislamiento y el impacto medioambiental.

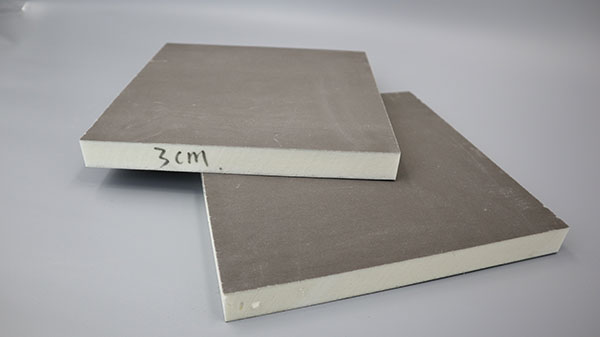

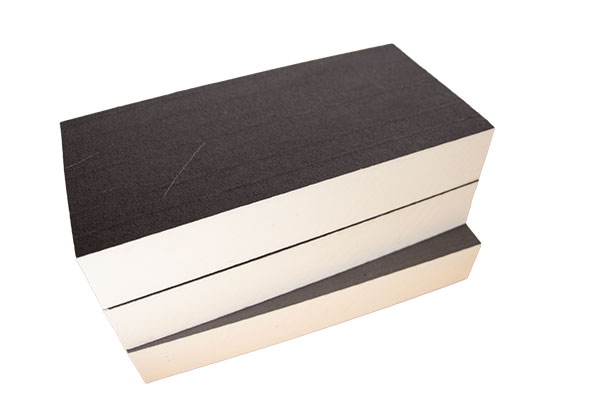

Aislamiento de poliisocianurato

El poliisocianurato es un aislante de espuma rígida compuesto por una estructura de celdas cerradas, normalmente revestida con una lámina o fibra de vidrio. Su alto valor R (aproximadamente de R-6 a R-6,5 por pulgada) lo convierte en una opción popular para tejados, paredes y aplicaciones bajo rasante. A diferencia de la fibra de vidrio o la celulosa, el poliisocianurato se basa en celdas rellenas de gas para resistir la transferencia de calor. Sin embargo, con el tiempo, los gases del interior de estas células pueden difundirse, reduciendo potencialmente el rendimiento térmico. envejecimiento térmico o deriva térmica.

¿Se degrada el valor R del poliisocianurato? La ciencia explicada

Las investigaciones indican que el aislamiento de poliisocianurato experimenta una disminución apreciable del valor R durante sus primeros años. Esto ocurre porque los agentes espumantes (gases como el pentano o los hidrocarburos) utilizados durante la fabricación se escapan gradualmente y son sustituidos por aire, que tiene menores propiedades aislantes. Así lo demuestran estudios realizados por organizaciones como la Asociación Nacional de Contratistas de Tejados (NRCA) y el Laboratorio Nacional Oak Ridge (ORNL):

- Pérdidas a corto plazo: La mayor parte de la desviación térmica se produce en los dos primeros años, con una disminución del valor R de 10-15%.

- Estabilidad a largo plazo: Tras este periodo inicial, el valor R se estabiliza, conservando aproximadamente el 85-90% de su valor nominal original.

Por ejemplo, el poliisocianurato clasificado como R-6 por pulgada puede establecerse en R-5,1 a R-5,4 después del envejecimiento. Este valor estabilizado se suele utilizar en los cálculos energéticos para los códigos de construcción.

Factores que afectan al rendimiento a largo plazo del poliisocianurato

- Temperaturas extremas: La exposición prolongada a altas temperaturas (por ejemplo, en tejados) acelera la difusión del gas.

- Exposición a la humedad: Aunque el poliisocianurato es resistente a la humedad, la infiltración prolongada de agua puede comprometer sus revestimientos y su núcleo.

- Calidad de la instalación: Un sellado o compresión inadecuados durante la instalación crean huecos, reduciendo el valor R efectivo.

- Material Grosor: Los tableros más gruesos presentan una difusión más lenta del gas debido a una menor relación superficie/volumen.

Comparación del poliisocianurato con otros materiales aislantes

Para contextualizar el rendimiento del poliisocianurato, considere los materiales de la competencia:

- XPS (poliestireno extruido): Pierde un valor R de 10-20% con el tiempo debido a problemas similares de difusión de gases.

- EPS (poliestireno expandido): Conserva casi el valor R 100% a largo plazo, pero tiene un valor inicial inferior (R-3,6 a R-4,2 por pulgada).

- Espuma en spray: La espuma pulverizada de célula cerrada conserva mejor el valor R, pero cuesta bastante más.

Aunque el valor R envejecido del poliisocianurato sigue siendo competitivo, su rendimiento depende de las condiciones específicas de la aplicación.

Normas industriales y métodos de ensayo

El aislamiento de poliisocianurato se somete a pruebas de envejecimiento acelerado (por ejemplo, ASTM C1289) para simular décadas de vida útil en entornos controlados. Los fabricantes deben informar valores R envejecidos basados en estas pruebas, lo que garantiza la transparencia. Sin embargo, las condiciones del mundo real -como la exposición a los rayos UV o los daños mecánicos- pueden causar desviaciones de los resultados de laboratorio.

Mitigación de la pérdida de valor R: buenas prácticas

- Utilizar datos envejecidos en fábrica: Especifique un aislamiento con valores R probados a largo plazo para un modelado energético preciso.

- Barreras protectoras: Instale retardadores de vapor o revestimientos reflectantes para proteger contra la humedad y las oscilaciones de temperatura.

- Inspecciones periódicas: Compruebe si hay compresión, huecos o daños por agua, especialmente en tejados o instalaciones bajo rasante.

Conclusión

El aislamiento de poliisocianurato experimenta una pérdida de valor R, principalmente durante los dos primeros años, pero después se estabiliza y mantiene la mayor parte de su resistencia térmica. Aunque no es inmune a la degradación, una instalación adecuada y la protección del medio ambiente garantizan que siga siendo una opción rentable y de alto rendimiento. Los constructores y los propietarios de viviendas deben dar prioridad a los valores R envejecidos por el fabricante y tener en cuenta los retos específicos del clima a la hora de seleccionar el aislamiento.

Para quienes evalúan el ahorro de energía a largo plazo, el equilibrio entre el rendimiento inicial, la durabilidad y el precio competitivo del poliisocianurato lo convierten en una opción viable, siempre que se tengan en cuenta sus limitaciones en el diseño y el mantenimiento.