In today’s pursuit of energy efficiency and sustainability in building construction, selecting the optimal foam insulation material is critical for reducing energy costs and enhancing living comfort. In the U.S. market, extruded polystyrene (XPS), spray polyurethane foam (SPF), and elastic rubber foam have emerged as mainstream options due to their superior performance. However, these materials differ significantly in terms of their application scenarios, costs, and environmental performance. This article will provide an in-depth analysis of the actual performance data and application cases of these three materials to help you make an informed decision.

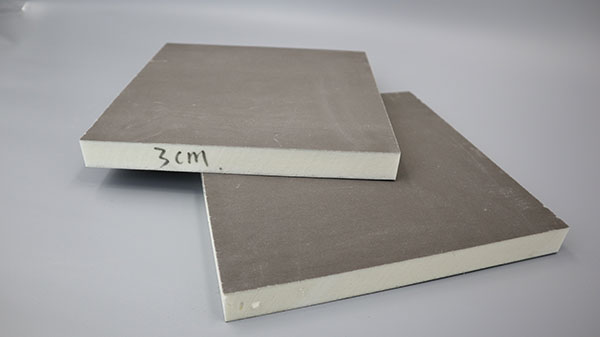

1.Extruded polystyrene (XPS): The preferred choice for moisture resistance and high strength

Extruded polystyrene (XPS) is a closed-cell rigid foam board that is an ideal choice for foundation, roof, and underground applications due to its excellent moisture resistance and compressive strength. Its core advantages include:

Exceptional moisture resistance: Water absorption rate as low as 0.05% (ASTM C272 test), significantly lower than other foam materials, maintaining thermal insulation performance even after prolonged immersion;

Exceptional strength: Compressive strength reaches 276 kPa (approximately 40 psi), enabling direct pouring of concrete layers, suitable for heavy-duty applications such as parking lots and sports stadiums;

Stable thermal resistance value: Provides R-5 thermal resistance per inch of thickness, with no degradation over extended use.

The Lincoln Financial Field in Philadelphia uses Owens Corning Foamular 404 XPS as its roof insulation layer, effectively protecting against the harsh winter cold. Its “sandwich” structure (rubber waterproof layer + drainage board + XPS + concrete) covers a total area of 32,000 square feet, ensuring the comfort of 66,000 spectators.

2. Spray polyurethane foam (SPF): The energy-saving champion with seamless sealing

Spray polyurethane foam (SPF) is divided into two types: open-cell (low density) and closed-cell (high density). When sprayed on site, it expands to form a seamless insulation layer, completely eliminating the cold bridge effect. The market is expanding at an annual growth rate of 9.2% and is expected to reach US$12.4 billion by 2030.

Significant energy savings: Reduces air leakage by more than 50% and lowers heating/cooling costs by up to 20%6;

Structural reinforcement: Closed-cell SPF can increase wall bending strength by 300%6;

Renovation tool: Particularly suitable for renovating old houses, filling wall cavities and irregular gaps.

Las Vegas’ “New American Home” uses Bayer’s open-cell SPF Bayseal, combined with solar panels and tankless water heaters, and has been awarded LEED Platinum certification, proving its effectiveness in extreme climates.

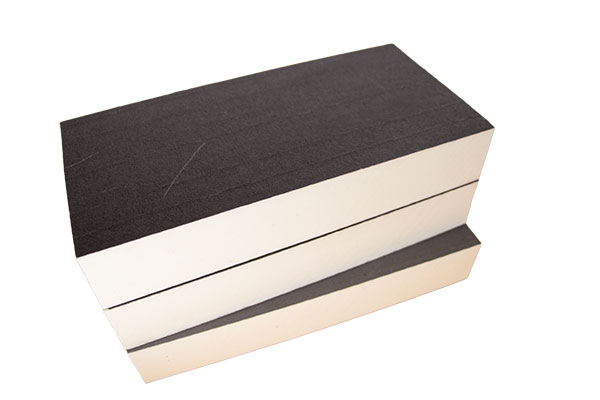

3. Elastic rubber foam: Professional protector of pipes and HVAC systems

Elastic rubber foam (such as NBR and EPDM) is the preferred insulation material for HVAC and industrial piping, with the market expected to reach US$4.1 billion by 2030. Its core characteristics include:

Anti-condensation: Closed-cell structure blocks water vapor, preventing pipe corrosion and mold growth;

Flexible and easy to install: Can be wrapped directly around curved pipes without special tools;

Noise reduction: Reduces HVAC system noise by up to 60%, improving indoor environmental quality.

Application tip: For chilled water pipes and refrigeration equipment, we recommend using medium-density foam with a thickness of ≥1 inch (30–80 kg/m³) to maximize thermal efficiency.

4.Comprehensive Performance Comparison: Which Foam Insulation Material is Best?

| Parameter | XPS Board | Closed-Cell SPF | Open-Cell SPF | Flexible Rubber Foam |

|---|---|---|---|---|

| R-value/inch | R-5 | R-6~R-7 | R-3.6~R-3.9 | R-3.2~R-4.2 |

| Moisture Resistance | ★★★★★ (Excellent) | ★★★★★ (Excellent) | ★★☆☆☆ (Fair) | ★★★★★ (Excellent) |

| Cost ($/ft²) | $0.50~$1.00 | $1.50~$3.00 | $1.00~$2.50 | $0.80~$2.00 |

| Installation Difficulty | Low (Board cutting) | High (Professional spray required) | High (Professional spray required) | Medium (Manual wrapping) |

| Eco-Friendliness | 20% recycled content | Partial bio-based | Low-VOC options | Recyclable |

| Best Applications | Foundations/Roofs/Slabs | Roofs/Exterior Walls/Basements | Attics/Interior Walls | Pipes/HVAC Systems |

5. Application Scenario Selection Guide

New residential roofs/foundations: Choose XPS (such as FOAMULAR® NGX) for strength and moisture resistance.

Old house renovations/wall filling: Choose open-cell SPF for affordability and improved airtightness.

Commercial building roofs: Closed-cell SPF provides higher R-values and integrated waterproofing solutions.

Industrial pipes/HVAC: Elastic rubber foam (such as Armacell) provides more reliable condensation prevention.

Sustainable construction: Look for GREENGUARD-certified products or those containing recycled materials (e.g., XPS with SCS certification).

Selecting the optimal foam insulation material requires a comprehensive consideration of specific application requirements: For high strength and moisture resistance, XPS boards are the preferred choice for foundations and concrete slabs; for seamless sealing and high R-values, closed-cell SPF is suitable for roofs and exterior walls; for budget-constrained applications requiring breathability, open-cell SPF is ideal for attic renovations; for pipe/HVAC insulation, elastic rubber foam is indispensable. As technology evolves, eco-friendly SPF and low-GWP XPS are becoming the market mainstream. It is recommended to focus on ENERGY STAR-certified products that balance performance and sustainability.